Do you know how you do what you do?

This video explains what Value Stream Mapping is, and why you should learn the technique. Value Stream Mapping was developed by Toyota and is known internally as Materials and Information Flow Analysis (MIFA). In this video I explain why I think it’s critically important to truly understand the power of this approach and why you should care.

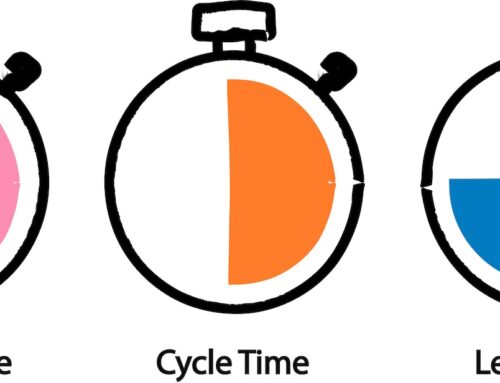

Value Stream Mapping (VSM) is a simple way to visualize how we do what we do; how we create value. VSM looks at 3 dimensions, people, products/objects, and information.

Information is often hidden, and while we see the products or work we often cannot see how information flows. Understanding the “flow of information” is critical in reducing costs, improving quality, and reduction in lead times. In short, the flow of value.

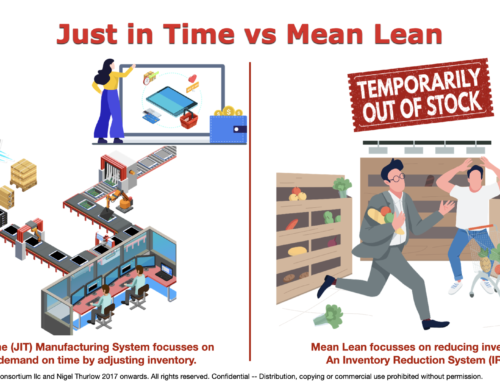

The Flow of value is not achieved through local optimizations, often the target of Lean kaizen blitzes or 6Sigma kaizen events, both an anathema to flow. You must view a system as a whole, and this means beyond those who do the actual technical work or construction tasks. An organizational system involves many discrete and dependent elements, such as HR, Procurement, Vendor Management, Legal, Compliance etc., as well as many external service providers. These are all part of the value stream. How they interact and collaborate is crucial to optimizing flow. Understanding precisely how they do this is where you start.

Remember: If you found this post useful and are not already a subscriber, sign up for the NEWSLETTER.